CNC Router Bit Types

In the world of CNC machining, precision and efficiency are critical, and achieving high-quality results depends heavily on selecting the right router bit for the task. With an extensive range of CNC router bit types available, understanding their functions and advantages is essential for woodworkers, machinists, and designers who want to make the most of their CNC machines. Each router bit type is designed to handle specific materials, make certain cuts, and create unique finishes, and choosing the right bit can mean the difference between an average outcome and a flawless product. Here, we'll explore the most popular CNC router bit types, breaking down their uses, benefits, and key applications.

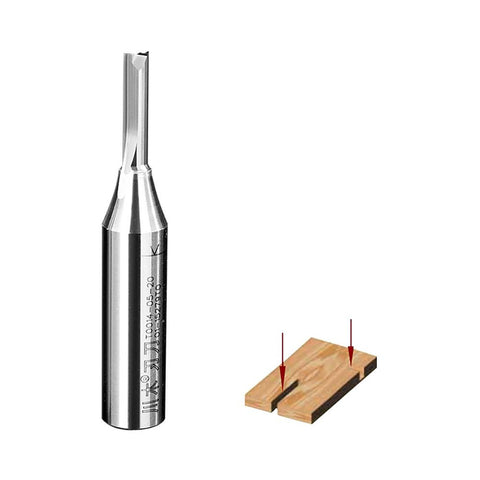

One of the most common and versatile CNC router bit types is the straight bit. Recognized for its simplicity and effectiveness, a straight bit cuts clean, straight edges, making it ideal for plunge cuts, dados, and rabbets. Straight bits work well for tasks that require simple cuts or removal of material from a flat surface, and they are often used in woodworking projects to create precise grooves, joints, and slots. Due to their straightforward design, straight bits are versatile enough for various materials, including wood, MDF, and certain plastics. However, they aren't ideal for more complex or intricate cutting jobs, as they lack the finesse of some specialized bits.

For projects that demand smooth edges or decorative finishes, the V-groove bit offers both versatility and aesthetics. Named for its V-shaped cutting edge, this bit excels at carving detailed lines, engraving, and chamfering edges. V-groove bits are popular in sign-making, as they create clean lines and precise angles, giving the finished product a professional look. The varying angle options of V-groove bits make them suitable for intricate designs, allowing users to adjust the depth and style of the cut to achieve the desired effect. In addition to wood, V-groove bits can also be used on plastics and composites, making them a staple for decorative work.

When precision and intricate details are the focus, ball-nose bits are invaluable. Featuring a rounded tip, ball-nose bits create smooth, contoured cuts, making them ideal for 3D carving, engraving, and shaping complex curves. Ball-nose bits are commonly used in relief carving, 3D modeling, and projects that require delicate, rounded edges. Their design ensures a smoother finish, as the curved tip minimizes the appearance of tool marks, which can be especially beneficial when working with softer materials. Ball-nose bits are preferred in artistic applications, like sculptures and sign-making, where intricate detail and a polished surface are required.

For cutting large material volumes quickly and efficiently, up-cut and down-cut spiral bits offer distinct advantages. Up-cut bits are designed to pull material chips upward, making them ideal for deep cuts and roughing work, as they help evacuate debris from the cutting path. This upward motion also helps prevent heat buildup, which is crucial for maintaining bit life and ensuring smooth cuts. However, the upward pulling force may cause tear-out on the surface of wood materials. Down-cut bits, on the other hand, push material chips downward, producing cleaner edges and preventing surface splintering, which is especially valuable in woodworking projects where a smooth finish is essential. Many CNC users opt for compression bits, which combine both up-cut and down-cut actions to achieve clean cuts on both sides of the material, making them ideal for laminates and plywood.

The cove bit is another essential router bit, particularly in cabinetry and decorative molding work. With a rounded cutting edge, cove bits create smooth, concave grooves and edges, adding an elegant touch to furniture pieces, paneling, and trim. Often used to create classic decorative profiles, cove bits allow woodworkers to enhance their designs by introducing custom, professional-looking edges. Cove bits are especially valued for their versatility in detail work, offering various radius sizes to achieve different looks and complement other decorative features.

For tasks requiring more aggressive material removal and shaping, surfacing bits are invaluable. Surfacing bits, often large and flat, are designed to flatten or plane surfaces, making them ideal for preparing stock or resurfacing workpieces that may be uneven or rough. In woodworking, surfacing bits are commonly used to level slabs and table tops, ensuring a perfectly flat surface for further processing. These bits work on both hardwood and softwood, as well as plastics and some non-ferrous metals. By providing a smooth, level base, surfacing bits help ensure that subsequent cuts and designs are accurate and consistent.

Finally, flush trim bits are a go-to for achieving uniform edges across multiple pieces. Flush trim bits have a bearing at the tip that allows them to follow a template or guide, trimming excess material to create an exact match to the pattern. These bits are widely used in pattern cutting, template routing, and edge trimming, providing an effortless way to replicate shapes and sizes precisely. With their precision and ease of use, flush trim bits are ideal for projects where consistency is key, such as creating duplicates or working with intricate patterns.

In CNC routing, selecting the right bit can significantly impact the quality, speed, and finish of the final product. From basic cuts to complex shapes, each CNC router bit type serves a unique purpose, allowing machinists and woodworkers to tailor their tools to the specific needs of each project. By understanding the strengths and applications of each bit type, CNC operators can make more informed choices, resulting in better efficiency, less waste, and a higher-quality finish. Whether creating simple grooves, intricate carvings, or smooth edges, the right router bit brings precision, creativity, and versatility to every CNC project. As technology advances, CNC router bit designs will continue to evolve, further expanding the possibilities for achieving professional-grade results in any material.